Trainers as Learning

A hands-on piece of lab equipment is where the magic happens – observations confirm knowledge learned and the many rabbit trails get narrowed down to the path most likely to produce success. It’s great to have the funds available to buy an off-the-shelf training system with developed curriculum. At other times, you have to get creative with what you have. By doing projects, you learn and your students learn far more than what’s in the off-the-shelf training guides.

Here’s a sample of projects I’ve created or guided students into fabricating.

Racing Car Simulator

Originally, this unit was built by the Electronics Program. The video game GRID provided the graphics and electrical signals that represented forces the driver would experience real time.

The Automation Program upgraded the DC gearmotor servo drives to a ACS SPiiPlus CM and a C#.NET operator interface. It featured pages for maintenace testing and calibration. It maintained a top-ten score list with driver’s name and score. It could also take photo with the driver’s score and post it to Facebook automatically when requested.

The simulator was quite compact after being upgraded and made many trips to high schools, career fairs and county fairs to promote the Automation program.

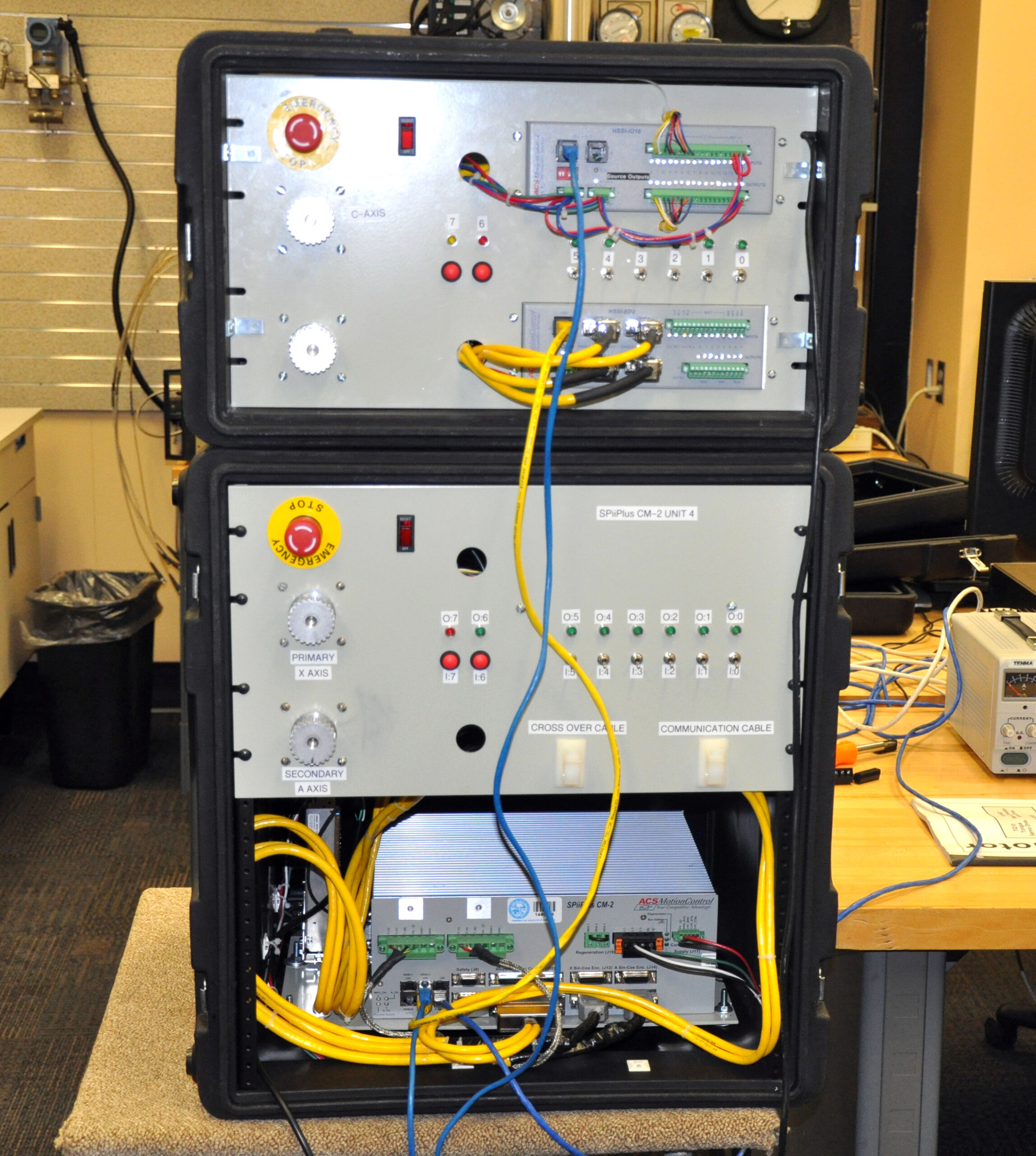

Multi-Axis Motion Control

ACS SPiiPlus CM 8-Axis Trainer and Remote Unit

ACS Motion Control offered a free software suite with advanced motion control capibilities, with full simulation and with advanced analysis tools. Students built four control units with two DC servo motors and four remote units with two DC servo motors.

Students would study topics like tuning, homing, host-follower, camming, position lock on a world class muti-axis controller. The SPiiPlus’s ability to control motion to sub-nanometer tolerances makes it the design engineer’s choice in the semi-conductor or medical industries.

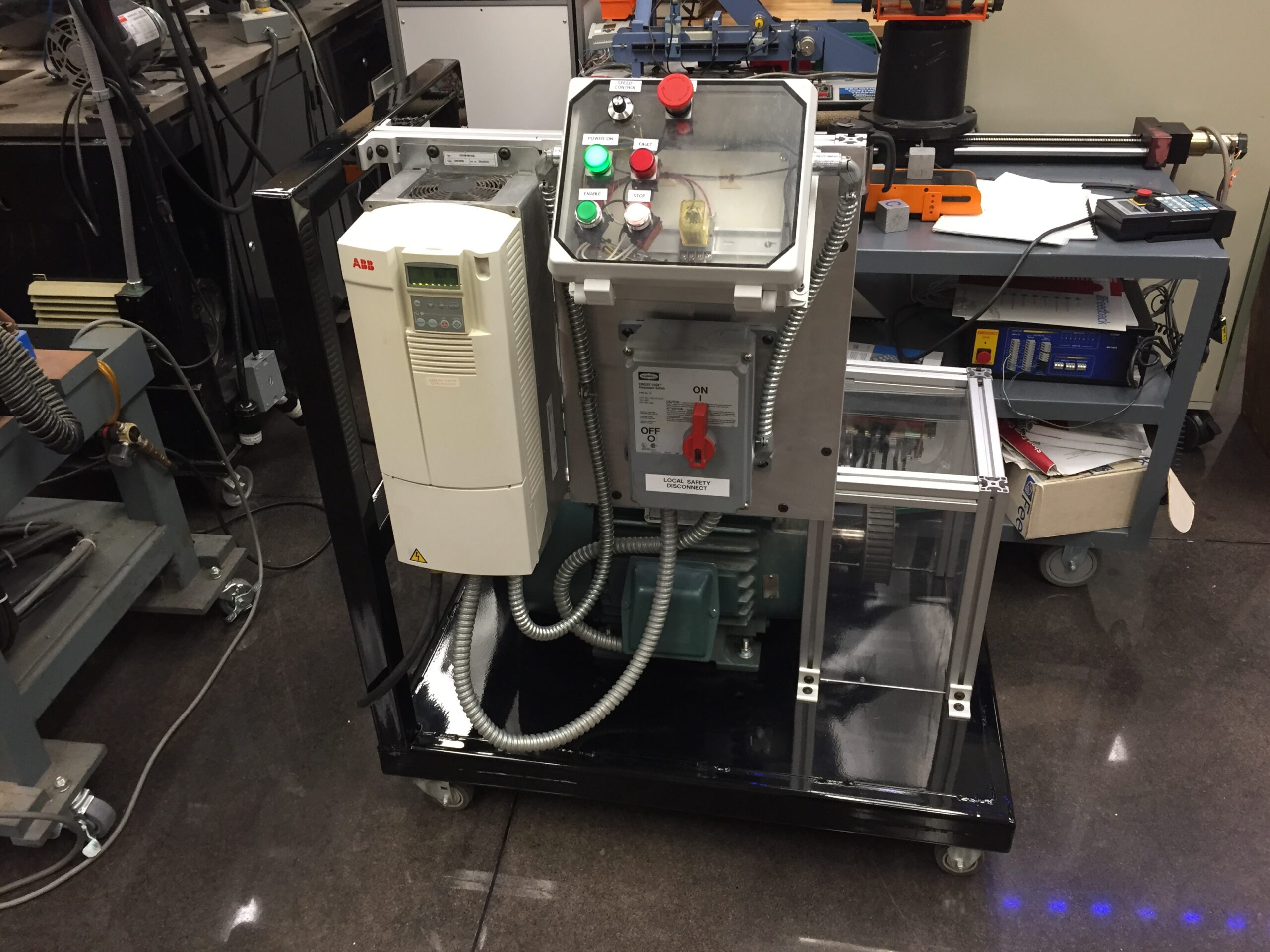

ABB Frequency Drive

25 Hp 460VAC Motor

A 25 Hp motor donation and a 20 Hp ABB frequency drive led to this trainer design. It featured a wired operator interface box and a lock out switch for motor servicing.

This trainer featured a three-phase knife switch between the frequency drive and the motor. Food processing lines need to do a LOTO for sprayout/cleanout every eight or twelve hours or when there’s a product change. Learners could lock-out the motor and see the status of the frequency change.

Bottled Water Line

This advanced process machine featured a few off-the-shelf components mounted on a student designed modular process line.

A hopper for the bottles picked out a bottle, put it in the right orientation, washed out the bottle, filled it with RO water, screwed on the cap and attached the label.

Label Aire Stand

Product labels are attached to boxes just after the product is boxed. The labeler is suspended over the conveyor system and is adjusted in height to ensure good label transfer as boxes travel under it.

This student designed stand was fully operational featuring accurate and stable height adjustements and secure labeler mounting. Powder coated black as a finish.

Adjustable Instructor Stand

This is one of my favorite motion control projects as I used it every day. A company donated a 500-pound force Thompson linear actuator. A student designed the stand. Another linear actuator for tilt. Powder coated black and she’s a beauty – very practicle too!

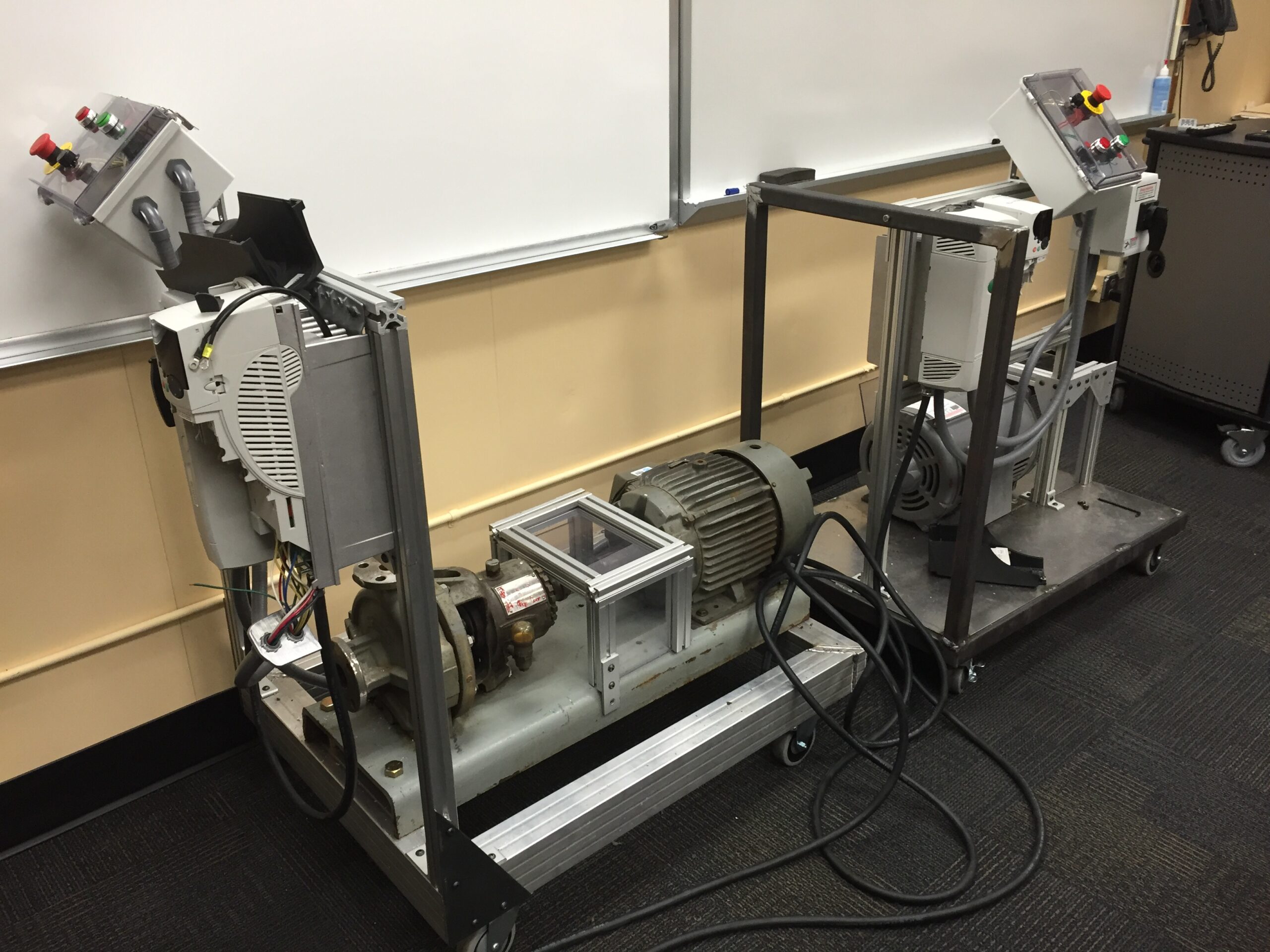

Emerson AC Frequency Drive

Two Emerson frequeny drive donations and two trainers. One had a industrial machine base with motor, coupler and a pump installed that could be used for laser alignment training. The other had a slightly imbalenced motor and was used for resonance training.

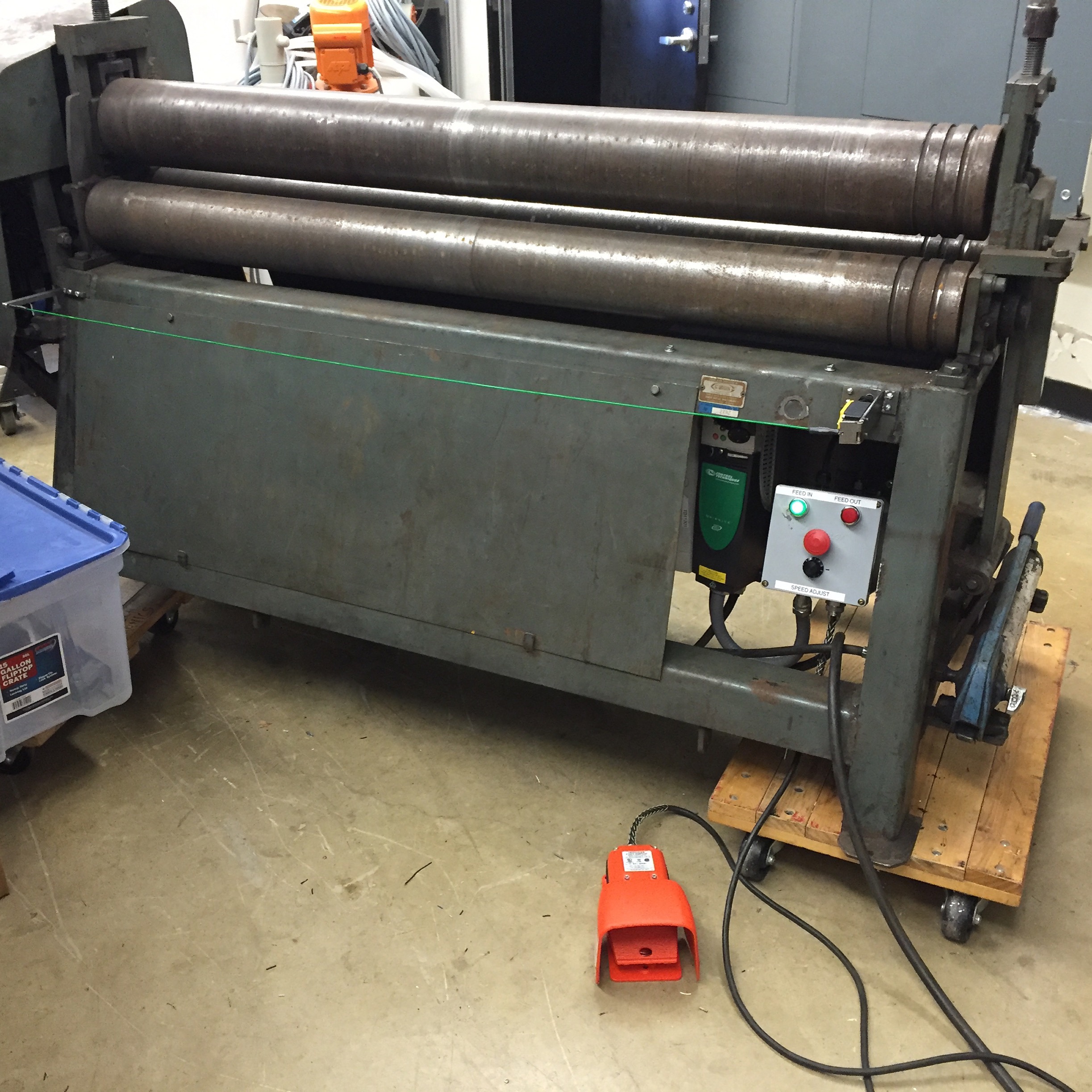

Sheet Metal Roller Safety Upgrade

We did a lot of projects with the help of the welding program. When they asked for help upgrading this old sheet metal roller, we took on the project. We added a frequency drive for adjustable speed control which also ramped up the speed slowly making it easier to control the feed. The added footswitch made the roller safer to operate.

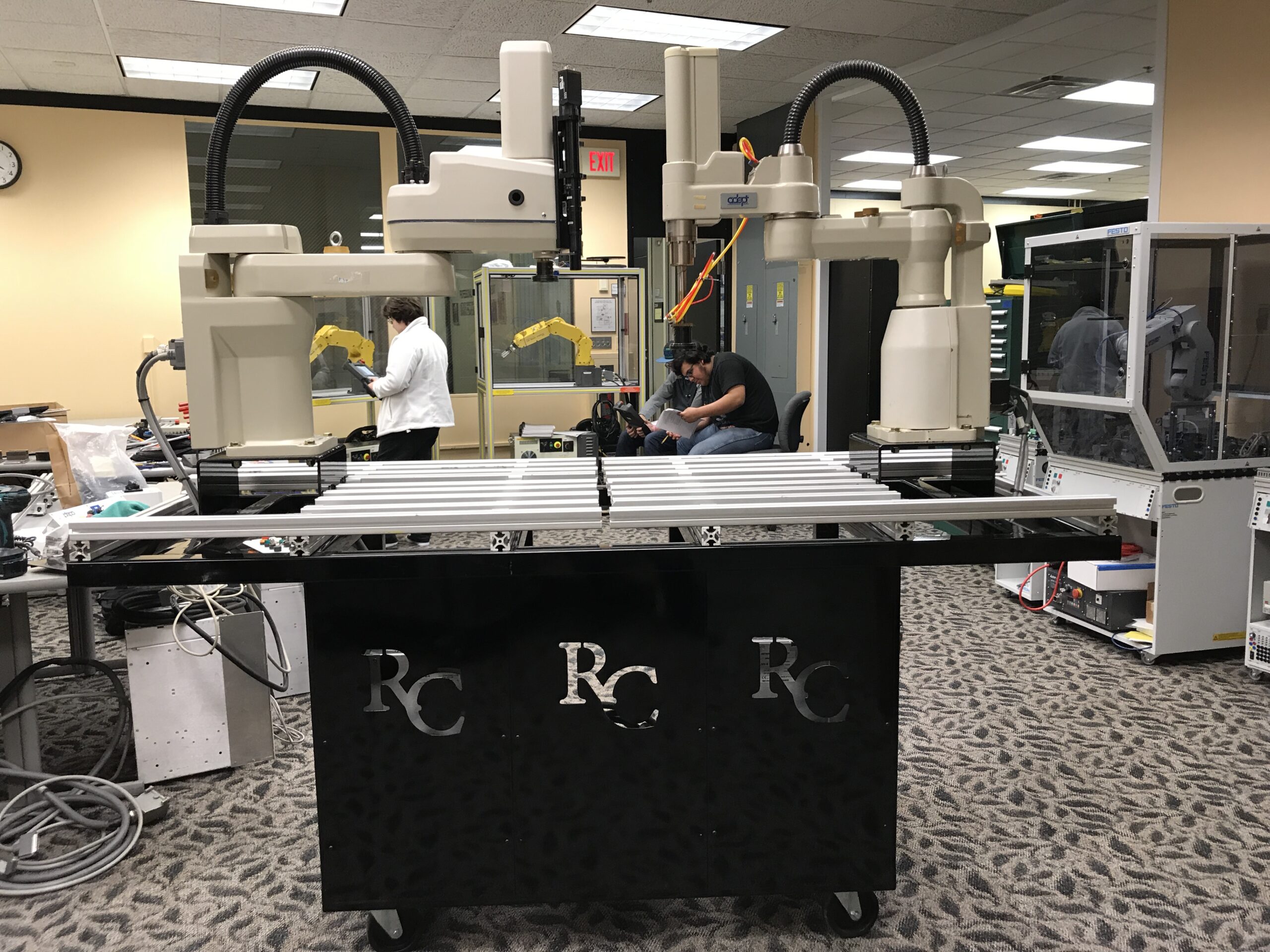

Dual Adept Robot Workstation

Several local manufacturers used hundreds of these Adept pick-and-place robots. We got a donation of four robots with controllers. We made two dual robot carts that could be operated independently or coordinate together passing parts between all four robots.

Mobile Multimedia Workstation

This teaching location had a lot of lab space, but limited areas for teaching students. This workstation could display videos, power points and demonstrate software actions. It had UPS backup and could be moved to a new location powered on.

It also featured a media computer running Adobe Preimeire Pro that could capture, edit, and render videos projects.

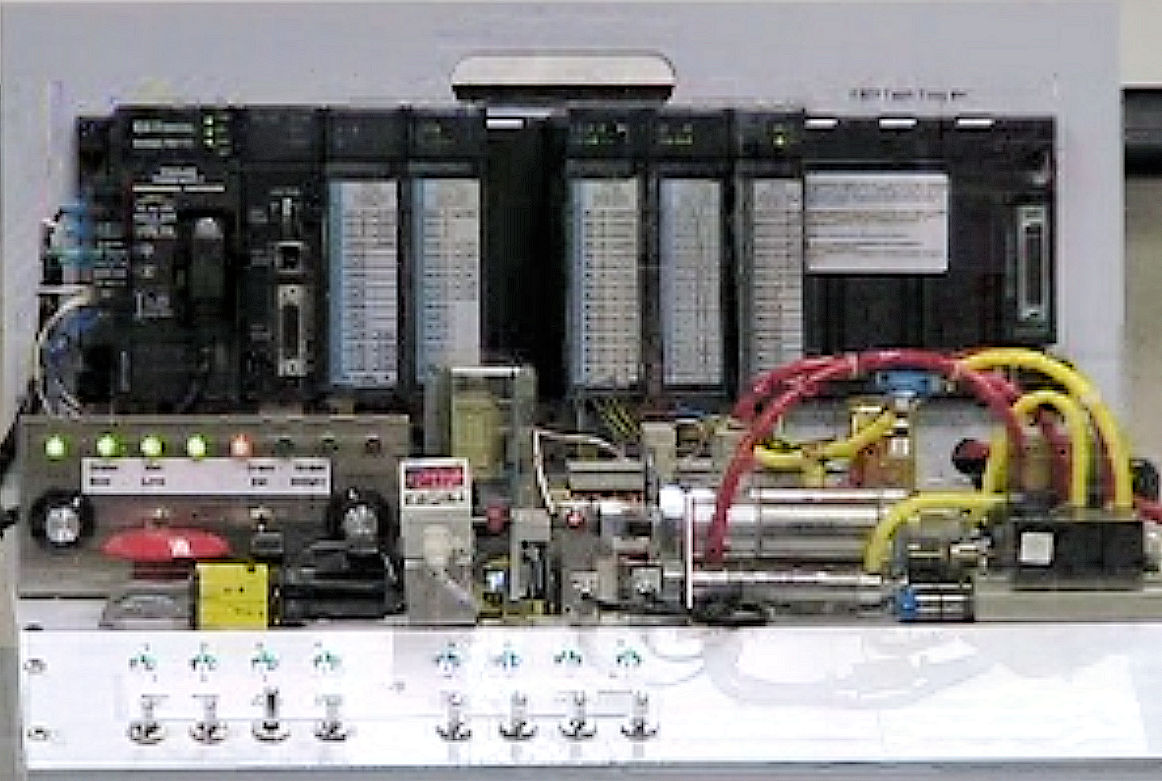

GE Fanuc 90-30 PLC Trainer

This compact GE 90-30 PLC trainer could do all the PLC lessons with it’s eight inputs and sixteen outputs, but it also served as a troubleshooting trainer.

It had three air cylinders, solenoids, a relay, a vacuum generator, a strain gauge, a vacuum gauge and an analog input. It simulated a process machine which could be sequenced as a programming exercise or a working sequence could have troulbles inserted.

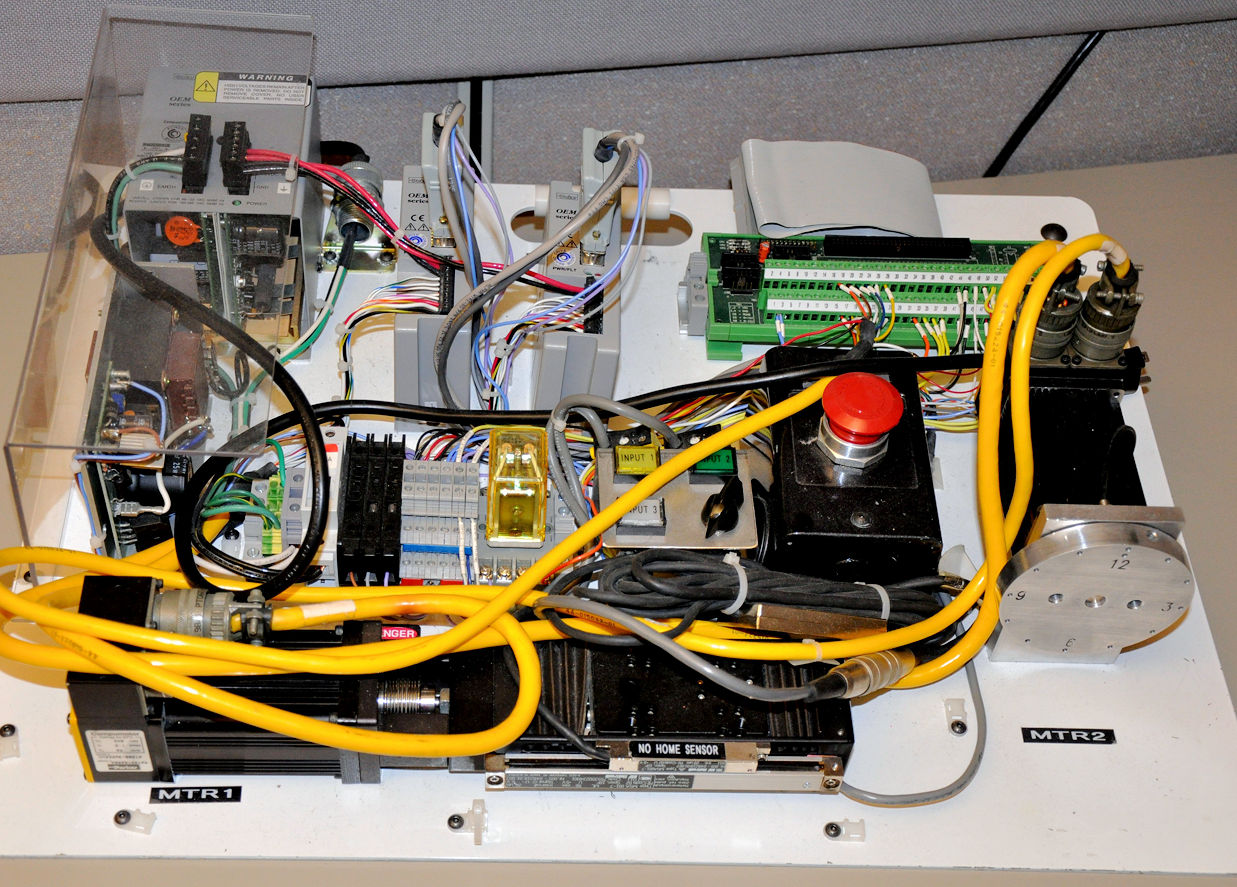

Delta Tau Multi-Axis Motion Control Trainer

This trainer was small to travel well, but featured full motion control learning experiences on both linear and rotary DC servo drives.

Topics like tuning, homing, limits, encoders, and synchronized motion were easily demonstrated on this trainer. A few inputs and outputs gave learning an opportunity for programming motion responses.

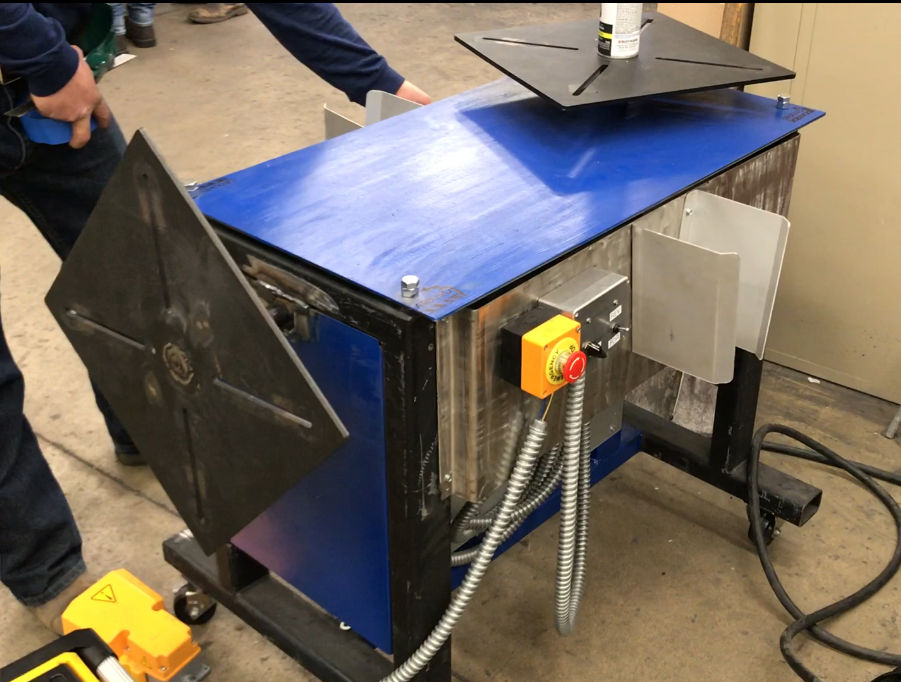

Rotary Welding Station

The Welding program did a lot of projects for us and here’s where we helped them out. A commercial rotary welding station would have cost north of $5k – this unit less than $600.

It featured a horizontal and vertical rotary stage with speed and direction controls for each. Seperate foot switches started and stopped motion. Both could be used at the same time with proper shielding.

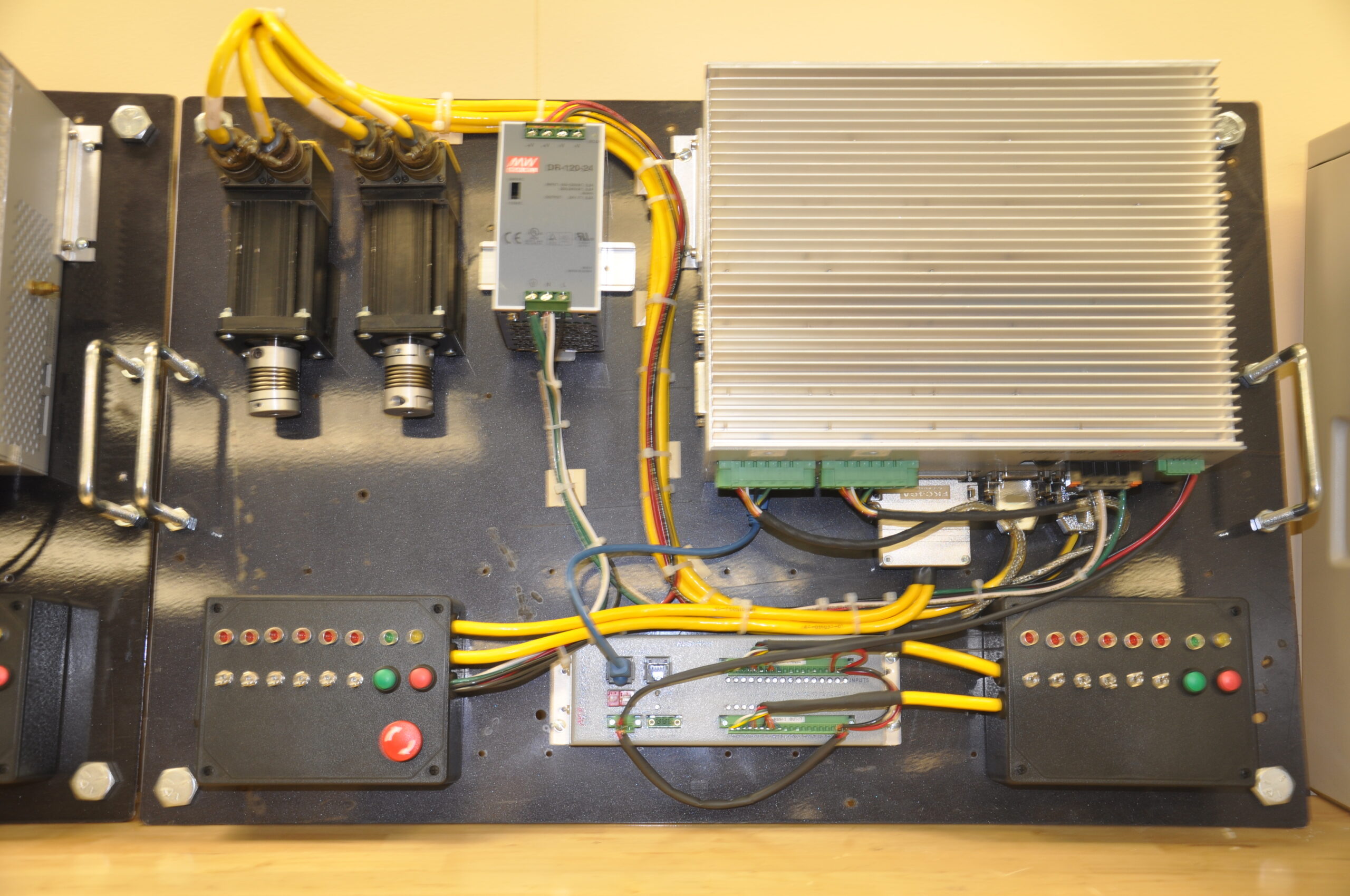

SPiiPlus CM Multi-Axis Motion Control Trainer

These eight-axis motion controlers with two-installed drives were selling new on Ebay for less than $500. Adding a remote IO block was easy with CAT5 Ethernet cable.

These world class controllers could control motion in the sub-nanometer range with extreme accuracy finding many applications in the medial and semi-conductor industries.

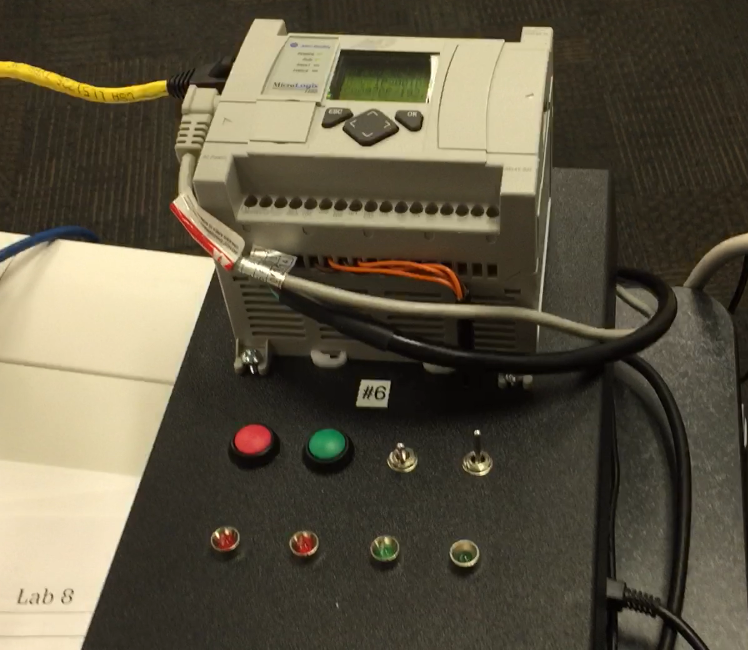

MicroLogix 1100 PLC Trainer

Allen-Bradley MicroLogix 1100 PLC

These PLCs featured both Ethernet and serial communication and a small display screen for status or setup or messages.

Allen-Bradley offered free RSLogix 500 Lite software package that also included RSLinx Classic.

We made the bases that held up to six inputs and six outputs. All of the eighteen holes were drilled with the 3D wood router. These were so versitle and inexpensive, we made over twenty-five of the trainers.

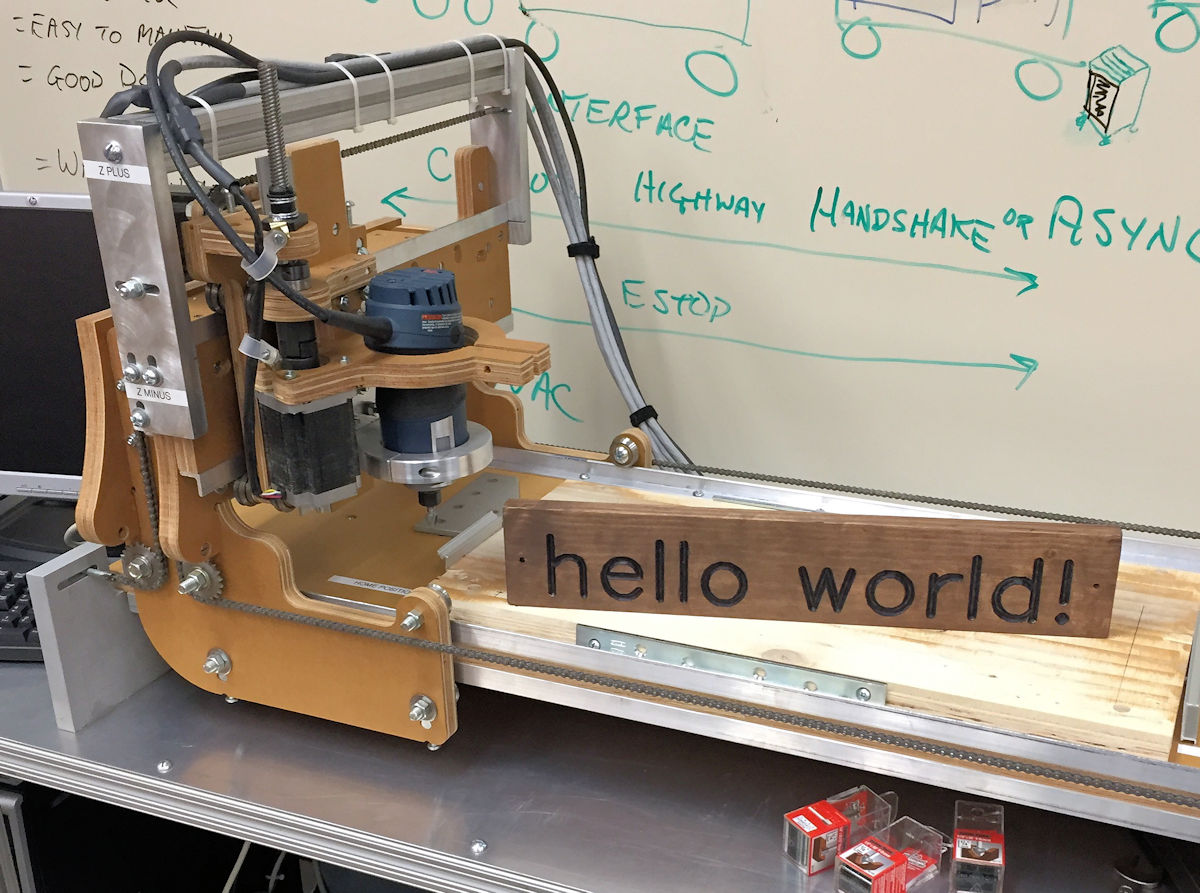

3D Wood Router

Here’s a project that came over from the Electronics program. All of the original parts were routed from plywood.

We analyzed the mechanism and replaced many of the parts with machined aluminum. The result is that the structure was much stiffer and routing projects had much better tolerances.

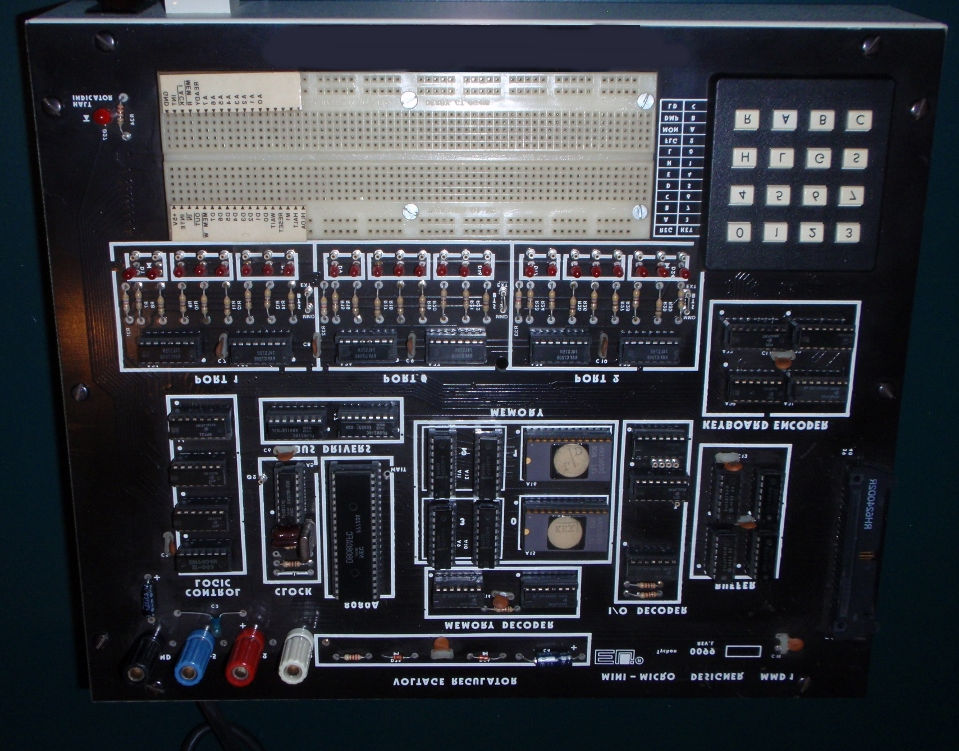

E&L MMD1 8080 CPU Trainer

In pre-internet days, all new technology learning came from magazines, newsletters and in person classes or clubs. I was stationed overseas and so that new technology seemed even more remote.

I decided to write a two-year associate degree program for microcomputer repair just so I could attend the classes. I mapped out everything I thought would be important to know to make repairs and upgrades. Surprizingly, the collage approved and funded the program.

I built six of these trainer kits that students used to build circuits demonstrating how to interface to 8080 CPU chip. The college found an instructor and I was able to attend two semesters learning about micro computers, their modification and repair.

GRID Racing Car Simulator

ACS SpiiPlus CM Trainer and Remote

ABB Frequency Drive Trainer

Water Bottling Line

Label Aire Adjustable Stand

Adjustable Instructor Stand

Emerson Frequency Drives

Sheet Metal Roller Safety Upgrade

Dual Adept Robot Stand

Mobile Multimedia Workstation

GE 90-30 PLC Trainer

Delta Tau Multi-Axis Trainer

Rotary Welding Station

SPiiPlus Multi-Axis Motion Control Trainer

MicroLogix 1100 PLC Trainer

3D Wood Router